Explore Our

Services

With today’s congested road right of ways, trained and experienced drillers are a must.

Directional Drilling (often referred to as Horizontal Directional Drilling or HDD) is a specialized trenchless construction method utilized for the installation of underground pipes, conduits, and cables. This innovative method allows us to navigate through layers of rock and sediment, reaching targets that were once thought unreachable.This method reduces environmental impact, making it ideal for areas where traditional excavation is either impractical or too disruptive.

Hydro excavation provides a flexibility to perform excavation with minimal chance of damage.

Hydro Excavating is a process which combines pressurized water and a high flow of moving air to excavate soil. The soil and water debris are evacuated by a hose connected to a collection tank. This controlled process not only allows for very accurate digging in a small amount of time but requires less labor, less backfilling and has a smaller impact on the environment.

Cable plowing is one of the most efficient and cost effective placement methods.

Plowing minimizes surface disruption and is commonly used for telecommunication lines, electrical cables, and other utilities in areas where trenchless methods are preferred. The cable plow creates a narrow horizontal trench in which the cable is directly fed into the trench as the plow advances. This simultaneous process ensures efficient and quick installation.

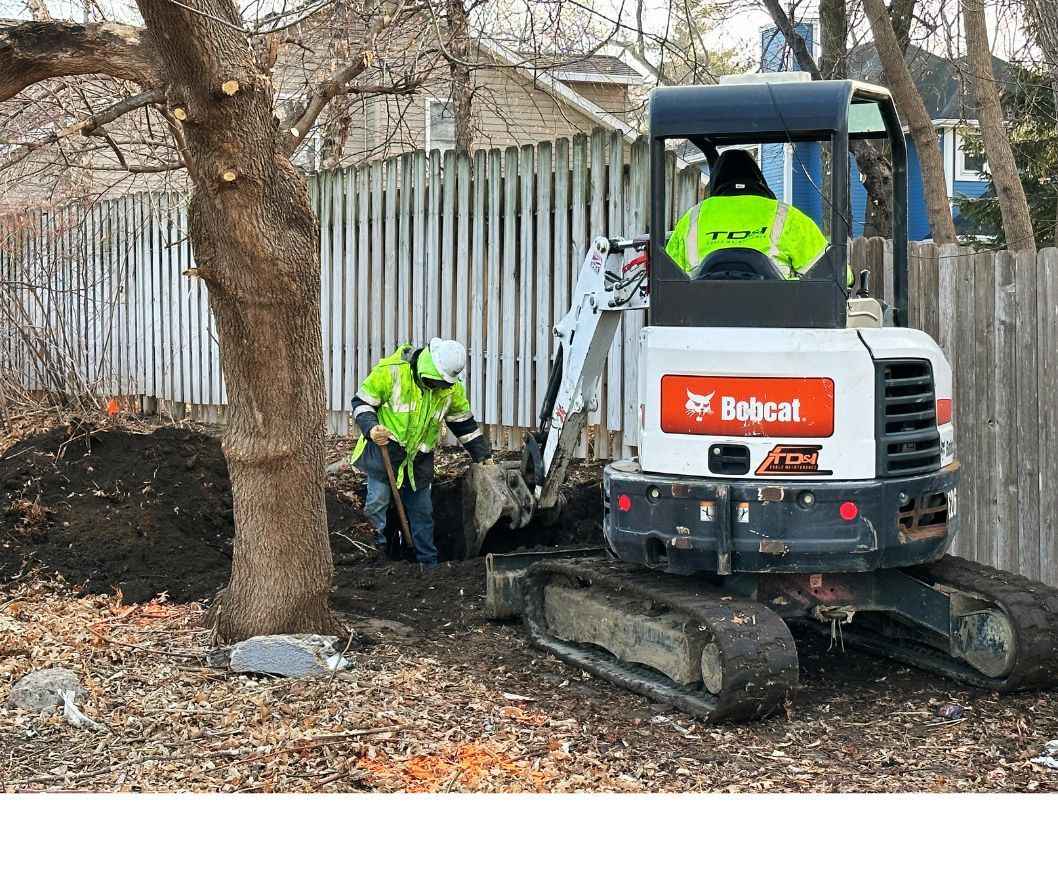

Trenching is one of the oldest forms of placing cable, but it has come a long way from the days of the pick ax.

Trenching, a fundamental technique in the realm of utility installation, offers a reliable method for laying underground cables. Whether for telecommunications, electricity, or internet infrastructure, trenching plays a pivotal role in burying cables safely and securely beneath the Earth's surface.

The final connection in cable installation.

Splicing involves the process of joining two or more cable segments together to create a continuous pathway for the transmission of electrical signals, data, or power. This technique is employed in various scenarios, including extending cable lengths, repairing damaged cables, or connecting cables of different types or sizes. Splicing requires specialized equipment, meticulous craftsmanship, and adherence to industry standards to ensure optimal performance and reliability.

Bridging gaps from above.

Aerial cable installation involves suspending cables above the ground, typically along utility poles or other support structures, to create pathways for the transmission of signals, data, or power. This method offers distinct advantages in scenarios where underground installation is impractical or cost-prohibitive, such as rugged terrain, water crossings, or densely populated urban areas.

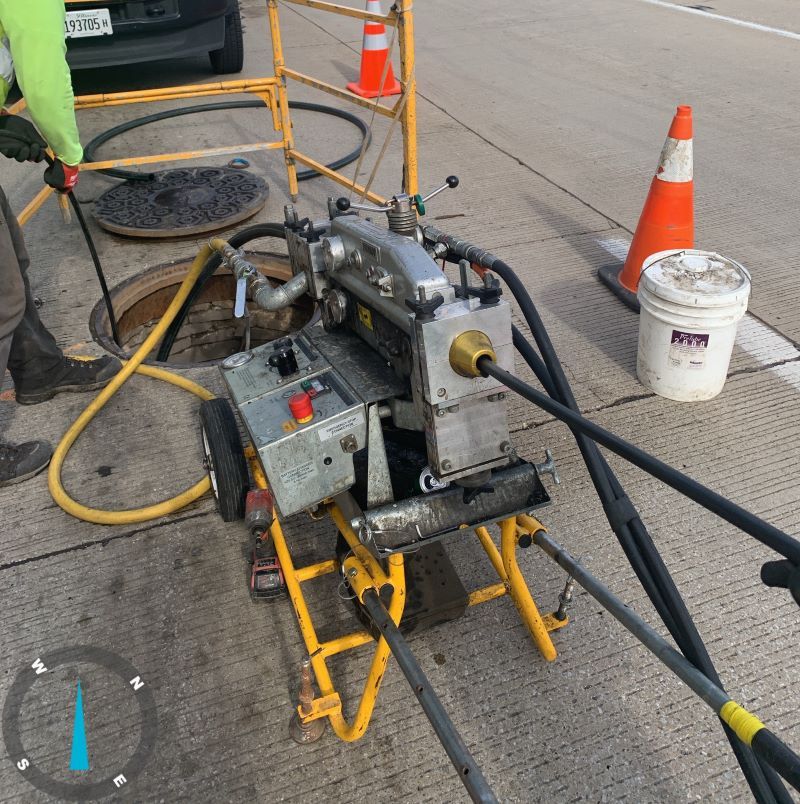

Fiber jetting, also known as microduct installation or air-assisted cable installation, involves the use of high-pressure air or water to propel fiber optic cables through pre-installed conduits or ducts buried underground. This method offers several advantages over traditional cable installation techniques, including reduced labor costs, faster installation times, and less disruption to infrastructure and landscaping.

Cable/duct pulling involves the installation of cables through pre-installed conduits or ducts buried underground. This method offers several advantages over traditional trenching or plowing techniques, including reduced disruption to the surrounding environment, faster installation times, and increased protection for the cables against environmental hazards.

"No project is too big or too small, and there's no deadline that can't be met"

Being a leader in the underground utility trade, we pride ourselves on our ability to get the job done in a timely and efficient manner. With a team of experienced individuals, you can be confident that all your organization's infrastructure needs will be met.

Safe. Fast. Efficient. Installation.

We want to know your organization's infrastructure needs so TD&I can provide the services to get the job done.